[High-performance boiler that made the most of our accumulated technology and experience]

In response to recent remarkable technological innovations, high-temperature (200 to 350°C) indirect heating systems are increasingly being used in various processes such as decomposition, reaction, distillation, dissolution, drying, and molding. Based on our accumulated technology and experience as well as the introduction of foreign technology, our thermal oil heater is highly trusted by users as a pioneering product that now has a proven track record of over 30 years. We can respond to such diversified needs as design and manufacturing while considering the entire system and establishment of our product line, and also have a reliable support system for after-sales service.

In pursuit of efficiency, safety and usability

| Reduced construction cost |

|

|---|---|

| Saving operation costs |

|

| System reliability |

|

| Improved product quality |

|

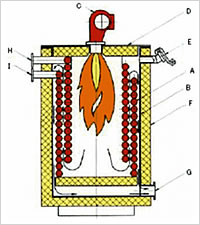

With the design using logical arrangement of heating surface aiming at efficient use of combustion heat and minimizing heat loss, a consideration to prevent maldistribution of heat medium oil by keeping low film temperature and a structure that allows removal of heating coil from a casing, all of these design concepts are combined and have successfully produced a compact and easy to use completed heat medium boiler.

A: heating coil

B: Casing

C: Burner

D: Unit cover

E: Pressure reducing valve

F: Insulation

G: Combustion gas

H: Heat medium oil inlet

I: Heat medium oil outlet

In case of small capacity (heat capacity less than 100,000kcal/hr), using the method of heating by electric heater would be advantageous.

By using SCR, the operation would be simple and the temperature could be controlled extremely accurately.