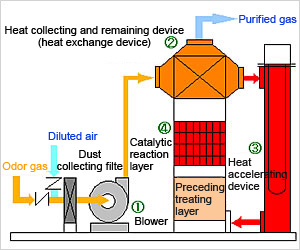

Our catalytic deodorizing equipment uses a precious metal catalyst to completely decompose foul odors, fermentation odors, ammonia odors and VOC (volatile organic solvent), which have previously been considered difficult to deodorize.

We have catalysts dedicated to foul odors, fermentation odors, and ammonia odors and catalysts dedicated to VOC (volatile organic solvent). Either or both of them can be selected depending on the details of the deodorization treatment needed.

- Pt honeycomb catalyst (at the top of the photo) Pt alumina ball catalyst (at the bottom of the photo)

- (We offer heat resistant catalysts to cope with high temperature of 700 to 800°C as well)

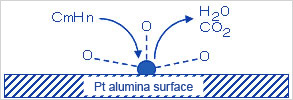

[Catalytic function]

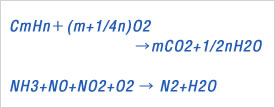

Harmful carbon monoxide and carbohydrates contained in exhaust gas discharged from factories are burnt to oxidatively decompose them into harmless carbon dioxide and water vapor. The high temperature of 700 to 800°C is necessary when no catalyst is used. However, when a catalyst is used, complete oxidative decomposition can be performed at the low temperature of 150 to 350°C.

Low-temperature combustion results in reducing NOx emissions. In addition, the combustion heat generated at the same time can be recovered and made effective use of.

- Catalysts can easily be combined to suit the purpose

- Complete oxidative decomposition is performed at low temperature (150 to 350°C)

- Uses honeycomb or spherical catalysts

- Generates very little NOx

- Exhibits superior oxidation activity

[Reaction temperature of various organic compounds and concentration after treatment]

| Organic compounds | Inlet gas temperature (°C) | Concentration before treatment (ppm) | Concentration after treatment (ppm) |

|---|---|---|---|

| Benzene | 210 | 380 | <1(Odorless) |

| Toluene | 210 | 320 | <1(Odorless) |

| MEK | 220 | 380 | <1(Odorless) |

| MIBK | 250 | 270 | <1(Odorless) |

| Methanol | 150 | 830 | <1(Odorless) |

| Acrolein | 180 | 500 | <1(Odorless) |

| Acetic acid | 350 | 590 | <1(Odorless) |

| Butyric acid | 250 | 370 | <1(Odorless) |

| Ethyl acetate | 350 | 350 | <1(Odorless) |

| Methyl mercaptan | 350 | 130 | Not controlled |

| Ethyl mercaptan | 350 | 50 | Not controlled |

| Hydrogen sulfide | 350 | 100 | Not controlled |

| Ammonia | 220 | 500 | <1(Odorless) |

| Trimethylamine | 220 | 40 | <1(Odorless) |

| Carbon monoxide | 150 | 4,000 | <1(Odorless) |

Pt-alumina catalyst was used at a space velocity of 20,000/h (equivalent at 0°C).

[Examples of cleaning the factory exhaust gas by precious metal catalyst]

| Type of industry | Exhaust gas component | Treated airflow (Nm³/min) | Treatment temperature (°C) | Treatment effect | |

|---|---|---|---|---|---|

| Catalyst inlet | Catalyst outlet | ||||

| Gravure printing | Toluene, ethyl acetate, IPA | 150 | 250 | 330 | 99% or higher |

| Offset printing | Aldehydes, ketones | 120 | 350 | 380 | C1 equivalent: 3ppm or less, odor concentration 100 |

| Automobile painting | Cationic electrodeposition coating | 230 | 350 | 380 | 96% or higher, odor concentration 120 |

| Printed-circuit board manufacturing | Methanol, Phenol, HCHO | 300 | 250 | 500 | 99% or higher |

| Can manufacturing | Toluene, MEK, MIBK | 160 | 350 | 550 | 98% or higher |

| Enamelled wire | Naphtha, cresol | 30 | 250 | 600 | 90% or higher |

| Casting | Phenol. ammonia, HCHO | 160 | 250 | 280 | 99.90% |

| Orange Juice | Burnt orange smell | 816 | 350 | 360 | Odor concentration 100 |

| Curry roux | Curry, garlic smell | 750 | 200 | 205 | Odor concentration 300 or less |

| Acrylonitrile manufacturing | Propane, propylene, CO> | 600 | 250 | 700 | 93% or higher |

(Note) The above data is extracted from delivered catalysts by N.E. CHEMCAT Corporation.